Analyze Reports

Nanolinter® analyzed for DTA, BET, PH. Analyze reports will be sent to you when you request. Please send a request email to info@nanolinter.com.

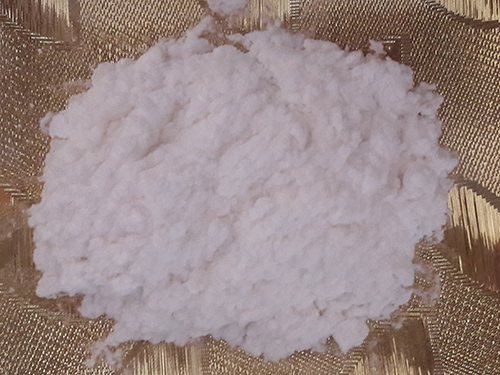

Nanocrystalline cellulose is a kind of nanomaterial that has got tens of nanometers width and hundreads of nanometers length and produced with the method of acid hydrolysis of amporphous structures of cellulose for isolating crystalline domains. Flax, hemp, coconout, banana plants and processed materials like paper pulp and microcrystalline cellulose are the common sources for producing nanocrystalline cellulose.

Aspect ratio, is a unitless number that

definites length/width ratio of nanocrystallites.

Nanocrystalline cellulose can have aspect ratio values between

1-100 respect to their production source [1]. As that can be

seen in Table 1, resources effects the final product directly.

Also crystal sizes effects the mechanical behaviour of

composites directly, too.

Table 1.

Comparasion of length and width values of nanocrystalline

celluloses from different sources [2]

|

Source |

Length [nm] |

Width [nm] |

|

Bacterial

Sources |

100-1000 |

10-50 |

|

100-1000 |

5-10 x 30-50 |

|

|

Cotton |

100-150 |

5-10 |

|

70-170 |

7 |

|

|

200-300 |

8 |

|

|

255 |

15 |

|

|

150-210 |

5-11 |

|

|

Cotton

Linter |

100-200 |

10-20 |

|

25-320 |

6-70 |

|

|

300-500 |

15-30 |

|

|

Microcrystalline Cellulose |

35-265 |

3-48 |

|

250-270 |

23 |

|

|

500 |

10 |

|

|

Ramie |

150-250 |

6-8 |

|

50-150 |

5-10 |

|

|

Sisal |

100-500 |

3-5 |

|

150-280 |

3,5-6,5 |

|

|

Tunicate |

- |

8,8 x 18,2 |

|

1160 |

16 |

|

|

500-1000 |

10 |

|

|

1000-3000 |

15-30 |

|

|

100-1000 |

15 |

|

|

1073 |

28 |

|

|

Valonia |

>1000 |

10-20 |

|

Soft Wood |

200-200 |

3-4 |

|

100-150 |

4-5 |

|

|

Hard Wood |

140-150 |

4-5 |

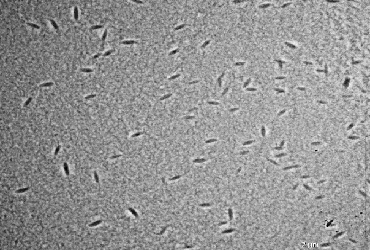

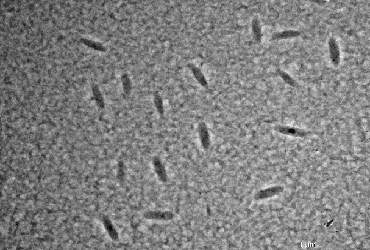

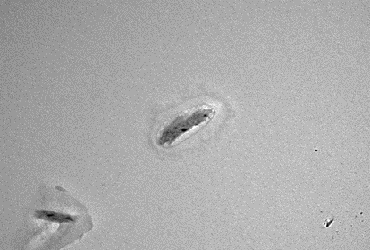

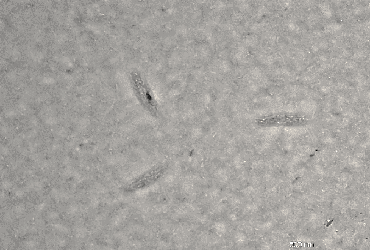

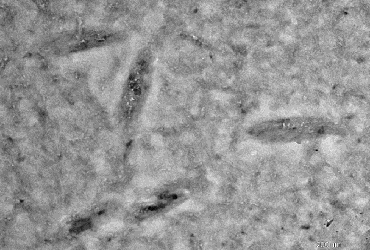

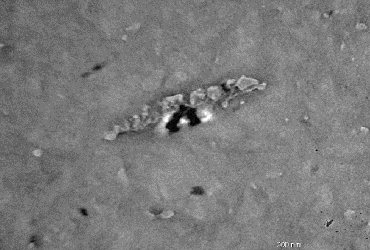

In our works, lignocellulosic and cotton plant derived linter and paper pulp were used as resource of nanocrystalline cellulose production. In Table 2, crystalline sizes that produced from treatment of cellulosic raw materials with sulfuric acid are given.

Tablo 2. TEM Analysis linked crystalline sizes of the nanocrystalline cellulose specimens that are derived from different sources

|

NCC from

Linter |

NCC from

Long Cut Paper Pulp |

NCC from Short

Cut Paper Pulp |

||||||

|

Length [nm] |

Diameter

[nm] |

Length [nm] |

Diameter [nm] |

Length [nm] |

Diameter [nm] |

|||

|

108,43 |

2,92 |

94,72 |

12,16 |

181,25 |

31,32 |

|||

|

160,74 |

2,97 |

104,41 |

13,21 |

193,56 |

44,44 |

|||

|

174,99 |

3,11 |

127,99 |

16,71 |

224,99 |

46,02 |

|||

|

188,75 |

3,23 |

173,12 |

17,23 |

318,8 |

54,41 |

|||

|

202,3 |

3,32 |

177,74 |

20,68 |

364,34 |

55,55 |

|||

|

205,75 |

6 |

188,79 |

25,07 |

386,73 |

66,32 |

|||

|

208,12 |

6,76 |

208,74 |

|

430,48 |

66,66 |

|||

|

214,78 |

7,88 |

326,1 |

|

|

66,66 |

|||

|

216,91 |

9,01 |

447,53 |

|

|

80,88 |

|||

|

232,09 |

16,33 |

|

|

|

87,64 |

|||

|

234,77 |

58,91 |

|

|

|

88,88 |

|||

|

240,93 |

61,45 |

|

|

|

88,88 |

|||

|

240,98 |

64,69 |

|

|

|

89,26 |

|||

|

251,91 |

64,69 |

|

|

|

111,1 |

|||

|

253,84 |

67,16 |

|

|

|

|

|||

|

253,93 |

71,44 |

|

|

|

|

|||

|

266,18 |

75,19 |

|

|

|

|

|||

|

269,45 |

75,73 |

|

|

|

|

|||

|

274,37 |

77,99 |

|

|

|

|

|||

|

278,84 |

|

|

|

|

|

|||

|

Mean

Values |

223,903 |

35,72526 |

205,46 |

17,51 |

300,0214 |

69,85857 |

||

|

Length/Diameter Values |

||||||||

|

Smallest Length/Smallest Diameter |

95,49315068 |

36,80345395 |

13,74457216 |

|||||

|

Smallest Length/Biggest Diameter |

1,39030645 |

7,789473684 |

1,631413141 |

|||||

|

Biggest

Length/Biggest Diameter |

3,575330171 |

17,85121659 |

3,874707471 |

|||||

|

Biggest

Length/Smallest Diameter |

37,13356164 |

7,789473684 |

5,787037037 |

|||||

|

Mean

Length/Mean Diameter |

6,267357612 |

11,73386636 |

4,29469745 |

|||||

Compatibility between results of our works and related literature can be easily seen from Table 2. Aspect ratio values are also given in Table 2.

Table 3. Comparasion of mechanical properties of nanocrystalline cellulose and industrial fibers [1]

|

Material |

Density

[g/cm3] |

Tensile

Strength [GPa] |

|

Kevlar 49

Fiber |

1,1-1,4 |

3,5 |

|

Karbon

Fiber |

2,5 |

3,5-4,5 |

|

Steel Wire |

7,8 |

4,1 |

|

Carbon

Nano Tube |

2,1 |

11-73 |

|

Glass

Fiber |

2,6 |

4,8 |

|

Nanocrystalline Cellulose |

1,6 |

7,5-7,7 |

Composite materials are the major application area of nanocrystalline cellulose. Nanocrystalline cellulose is more strengthful material than steel with 145 GPa elasticity modulus and more stiffer than aluminium with 7,5 GPa tensile strength but also less dense material than others [1]. As it can be seen in Table 3, density values of nanocrystalline cellulose is close to the Kevlar fiber but nanocrystalline cellulose has got two times better mechanical properties. Nanocrystalline cellulose is much stregthful and less dense material compared to common fibers that are use in composites and also more renewable material than its closest rival “carbon nano tube”.

Table 4. Comparasion of mechanical behaviour of nanocrystalline cellulose reinforced composites [3]

|

Matrix |

NCC-Source and Size

[Dia., Len. [nm]] |

%NCC [wt %] |

Increase on Young

Modulus [%] |

Increase onTensile

Strength [%] |

Increase on Elongation

at Brake [%] |

|

Polyethylene Oxide |

Bacterial [11, 420] |

0-0,4 |

139,9 |

72,3 |

-233,3 |

|

Polyacrylic Acid |

Cotton |

0-20 |

7633,9 |

5658,6 |

-99,9 |

|

Polyethylene Oxide |

MCC [10, 112] |

0-20 |

392,1 |

240,8 |

-37,5 |

|

Cotton [5-10, 40-100] |

0-20 |

190,5 |

377,5 |

-33,5 |

|

|

Tunicate [20, 2000] |

0-15 |

98,8 |

- |

- |

|

|

Polyvinyl alcohol |

Ramie [3-10, 100-250] |

0-15 |

270,9 |

- |

- |

|

Polycaprolactone |

Ramie [3-10, 100-250] |

0-7,5 |

64,3 |

37,2 |

49,0 |

|

Polystyrene |

Paper [10-20, 200] |

0-9 |

60 |

- |

- |

|

Polymethyl methacrylate |

Bacterial [15-20, 300-8μm] |

0-20 |

- |

- |

- |

|

Wood [17, 190-660] |

0-41 |

17 |

30,2 |

-1,4 |

|

|

Polylactic acid |

MCC [92, 124] |

0-10 |

37 |

30,2 |

-1,4 |

|

EVOH |

Bacterial [30

nm] |

0-8 |

- |

- |

- |

|

Polylactic acid |

Cotton |

0-12,5 |

- |

161,9 |

- |

|

Silk |

Wood bark [25-40, 400-500] |

0-4 |

300,3 |

208,0 |

-55,6 |

In Table 4 effects of different sources like cotton, ramie and MCC derived nanocrystalline cellulose reinforced matrixes like polyethylene oxide, polyacrylic acid and polyvinyl alcohol on mechanical properties has been monitored. As it can be seen on related table nanocrystalline cellulose gives advanced mechanical properties to reinforced material.

Nanocrystalline cellulose has got exiting and potential application areas like paper, painting, building, and aerospace materials, food and drug additives because of its advanced mechanical properties and biocompatible, biodegredable, renewable and chemically modifiedable structure.

1. Peresin, M.S., A mini-review on

properties of nanocrystalline cellulose and its potential

applications. Revista Investigaciones Aplicadas, 2013. 7(2): p.

58-73.

2. Habibi, Y., L.A. Lucia, and O.J. Rojas, Cellulose

nanocrystals: chemistry, self-assembly, and applications.

Chemical reviews, 2010. 110(6): p. 3479-3500.

3. Zhou, C. and

Q. Wu, Recent development in applications of cellulose

nanocrystals for advanced polymer-based nanocomposites by novel

fabrication strategies. 2012: INTECH Open Access Publisher.

Nanolinter® is a nano-sized, linter based product that is developed for a producing an advanced technology material with consultancy of Yıldız Technical University, Chemistry- Metallurgy Faculty. Patent applications have been done for the Nanolinter® and feasibility studies are going to be started with the demands of industry.

Nanocrystalline cellulose is a material which has got increasing interest for researches, productions and applications. Nanocrystalline cellulose can be used as reinforcement material in sectors like composites, drugs, cosmetics, chemie, materials and paintings. Nanolinter® is producing with linter that is very abundant in Turkey and has got Industrial symbiosis benefits.

Production method of Nanolinter® is protected with the application to European Patent Office (EPO) at 04.02.2016. (legal protection covers 38 countries)

Transmission Electron Microscopy (TEM) images in this website is belongs to website owner according to laws. Situations like copying and sharing at other medias are defined as a crime at law for whatever reason it might be.

Contact Form

Address